Here’s another Eberspacher control unit, this time from an ancient D5W 5kW water heater. The system in this case is just flaky – sometimes the heater will start without fault & run perfectly, then suddenly will stop working entirely.

The error codes are read on these very old units via an indicator lamp connected to a test terminal. In this case the code was the one for Overheat Shutdown.

Considering this fault occurs when the heater is stone cold, I figured it was either a fault with the sensor itself or the ECU.

The temperature sensor is located on the heat exchanger, right next to the hot water outlet fitting. I’m not sure what the spec is, but it reads exactly 1KΩ at room temperature.

The PCB is held into the aluminium can by means of crimps around the edge that lock into the plastic terminal cover. Inserting a screwdriver & expanding the crimps allows the PCB to be slid out.

The factory date stamp on the microcontroller dates this unit to March 1989 – considerably older than I expected!

Unlike the newer versions that use transistors, this ECU has a bunch of PCB relays to do the high current switching of the water pump motor, fan motor & glowplug.

Overall the board looks to be solidly constructed, with silicone around all the larger components.

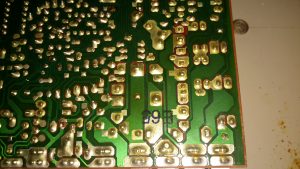

Here’s the solder side of the PCB, which has a generous coating of sealant to keep moisture out.

Looking at the solder joints for the row of relays on the top side of the PCB, it looks like that there’s some dry joints here.

I suspect that years of vibration has taken it’s toll, as the relays are otherwise unsupported. It wouldn’t be possible to use silicone to secure these devices as they are completely open – any sealant would likely stop them from operating.

Using a very hot soldering iron I managed to get the joints to reflow properly, using lots of flux to make sure the conformal coating didn’t interfere with the reflow.

Dear Sir,

I find this article with a google search. I have the same model but no documentation – no pinout or.I have all elements that seems to bo ok. Can you help me with more information? Thank you in advance!

Mihai CIOCA – mihai.cioca@gmail.com

Thanks for publishing this repair.

These heaters are very old but built like a tank, they keep going for many years.

Faults on them are usually due to 2 reasons.

1 corrosion on wire joints, fuses and connectors.

2 Poor soldered joints like you found.

Vibration is a contributing factor to cracked solder joints but not the only one.

Firstly when manufactured the board passes through molten solder.

The thicker metal leads do not heat up as much as thin ones so sometimes soldering is less good.

Secondly thermal expansion / contraction can break the joint over time.

As you found getting the solder to flow can sometimes be difficult as the metal tarnishes.

Best to remove the old solder with a solder sucker or wick, clean the metal then re-solder.

Flux definitely helps but many users do not have any, only resin cored solder.

We show similar solder joint problems on air heaters on our site.

This site gives many pages of free DIY advice on Eberspacher heater fault finding and repair.

We also can provide free pdf copies of manuals which your first reply asked for many years ago.

Many forum sites do not like publishing urls as it is considered to be advertising so i will not give it here.

Just do a Google search for Eberspacher and look for a site with varnish in its name.