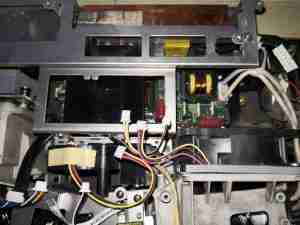

Time for another projector! This one was brought to me with a fault, described as a shadow in the middle of the image, shortly after the lamp was replaced after exploding. This is an older DLP projector, with a UHP mercury lamp. I’ve already removed the top cover of the projector here, showing the internals. The light engine is along the front of the unit, with the lamp on the right. The main control board on top contains all the image processing logic & control functions.

The other side of the mainboard holds the processing chipset. This is probably one of the biggest flip-chip BGA packages I’ve ever seen, the DDP2000. Along with the DAD1000 on the right, these format & send the image data to the DLP chip, via the large white header.

After the mains PCB is removed from the chassis, the rest of the light engine is visible. The DLP is hidden on the left, behind the large heatsink & interface PCB. The light engine is spread out a lot more on this projector, across the entire front of the unit.

A closeup of the light engine shows the back of the phase sensor for the colourwheel, and the mounting brackets for the optics.

The dichroic colourwheel is tucked into the gap between the lamphouse & the first optic.

Hiding at the back of the projector is the alloy frame holding the power supplies & cooling ducts.

After removing the brackets, the DC power supply & the lamp ballast are visible. Since this projector uses a UHP arc lamp, the DC power supply which has the usual low voltage outputs for the logic board, has an auxiliary output from the +340v rail after the PFC circuit that supplies power to the lamp ballast.

The lamp ballast is a pretty standard design, using an Osram control board.

After removing the top cover with the colourwheel, the main optic chain is visible. The usual mirror tunnel homogenizer at the start, with a convex & aspheric lens on the left.

The lamphouse has a last-resort thermal cutout to shut the ballast down if the cooling fans fail. These lamps output some serious heat, and likely wouldn’t last longer than a couple of minutes without cooling.

The final turning optics before the DLP chip are hidden in the Mg casting of the light engine.

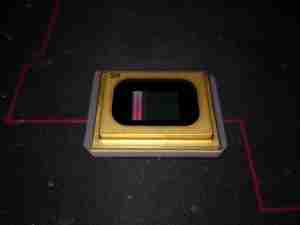

The DLP is the older type, with the large ceramic LGA package.

After the DLP, the light is routed through the objective lens, to the screen. This is the back of the lens inside the light engine.

And here is the main problem with the projector – the last lens in the optical chain before the DLP chip has been roasted by the intense light flux from the lamp. Unfortunately NEC cheaped out on this one – it’s the only optic in the machine that isn’t made of glass. This was likely caused by some contamination on the lens, which starts the process of absorbing light on the surface. The resulting heat then causes discolouring of the lens, which absorbs more heat. A chain reaction ensues, ending in the lens completely destroying itself.

The projection lens has a couple of sensors, for the focus & zoom, along with a focus motor. This is driven by feedback from a distance sensor in the base so no manual focusing is required.

You say cheaper out…

… I suggest it’s life expired … can’t sell a new one or shut down the second hand market of they last forever