I bought two of these packs for my new DeWalt combi drill, as the branded packs are very expensive and there’s unlikely to be much of a difference in cells used. I was a little mistaken on this, as you’ll see!

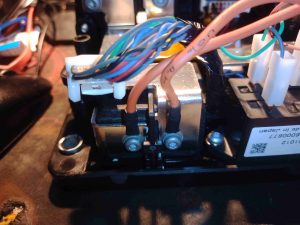

The top of the unit has the battery connections, with all the cell balance lines, along with an ID pin, and a TH pin. The TH pin connects a 10K NTC thermistor up to B+.

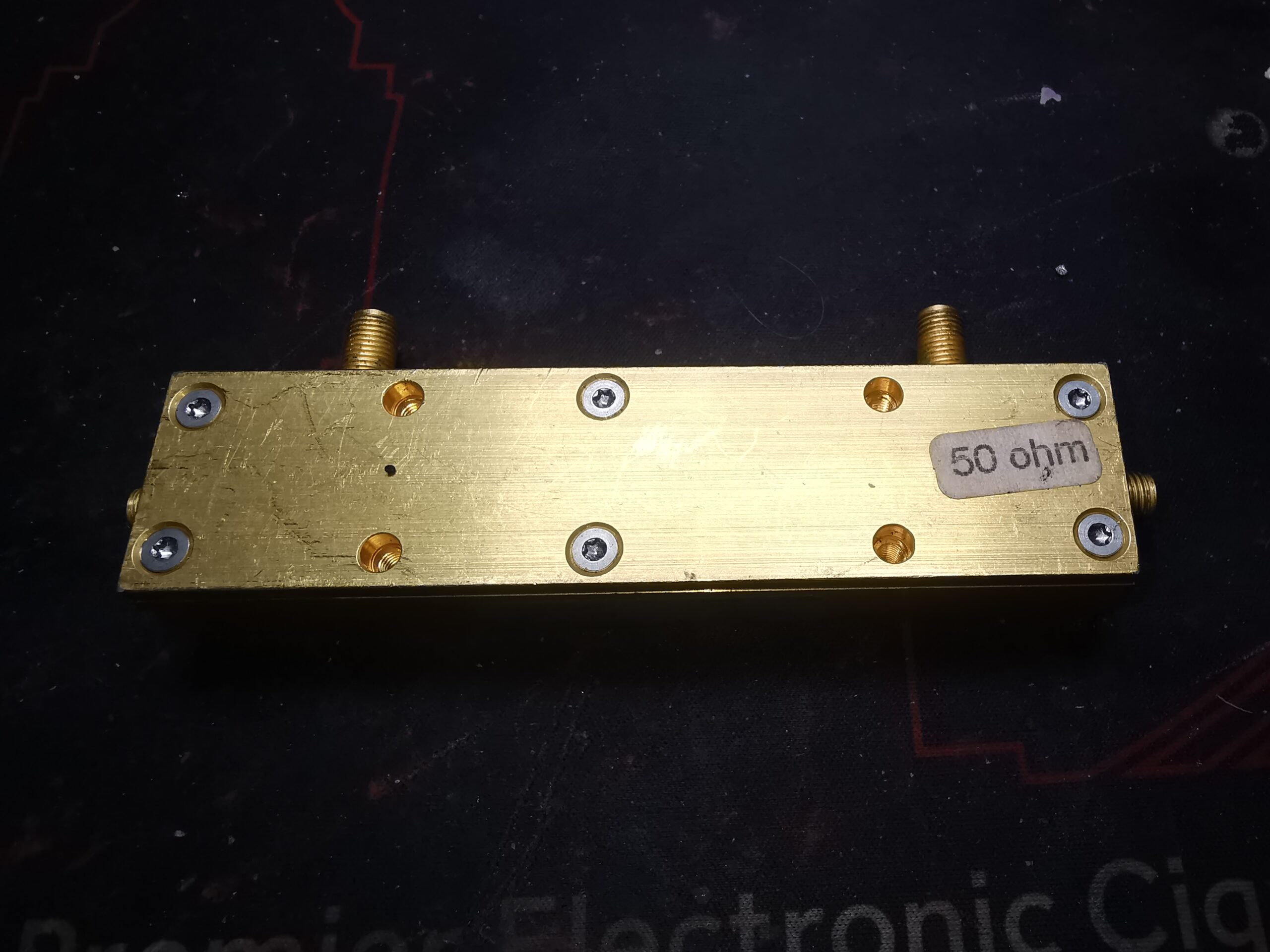

The bottom of the unit has the rating & warning label. This claims to be a 6Ah pack, but it’s nowhere even close!

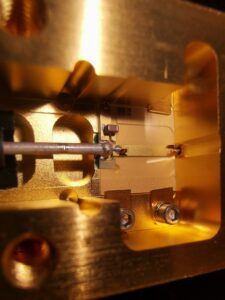

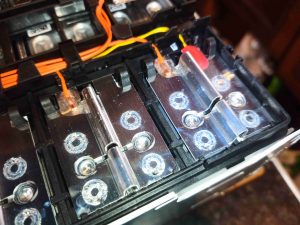

Removing 4 Torx screws gives access to the internals. The cells are all fitted into a plastic holder. There’s a small PCB holding the connector pins, and all the cells connect up to this for the balance outputs. There’s a small PCB on the side of the pack that holds the components for the battery meter.

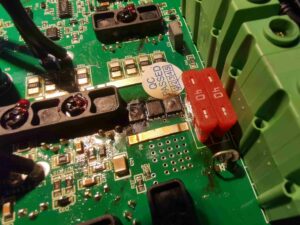

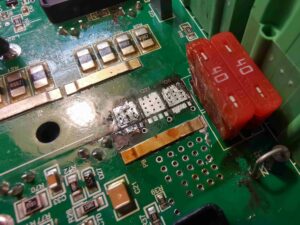

The back of the connector PCB has some passive components, but not much else. There’s the connections for the NTC at the bottom right of the board. There is an IC on this board, on the other side, but without desoldering all the pins, it’s not possible to see properly as it’s mainly hidden by the connector frame.

Not much on the front of the battery meter board, apart from the 3 bright green LEDs and the tactile switch.

The other side has a small ST microcontroller, a TL431 shunt reference, and some other passives.

All the cells are linked together with hefty interconnects, as expected for a high current pack. This is laid out as a 5S2P configuration, giving 21V max, 15V flat. Unfortunately I can’t see any markings on the cells – they may be off brand, or pulls from other products.

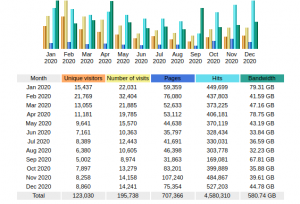

I figured as I always do with Chinese battery packs that the stated capacity of 6Ah was too good to be true, so I ran my usual cycle tests to see what the real capacity was, and was met with the following results:

| Cycle Number | Pack A | Pack B |

|---|---|---|

| 1 | 3969mAh | 3917mAh |

| 2 | 3963mAh | 3947mAh |

| 3 | 3961mAh | 3956mAh |

| 4 | 3953mAh | 3959mAh |

As can be seen from the table, these packs are 4Ah, not 6Ah. 2Ah cells sort of make sense for a pack like this, as the high-current capacity cells tend to be a lower capacity.